Introduction to Graphene

Graphene is currently the thinnest and hardest new material known to man. If you

were to stack 100000 single-layers of graphene it would equal the thickness of a

single hair. Its hardness is three times that of diamonds and 100 times that of

steel. In 2010, Andre Haim and Konstantin Novoselov, scientists from the

University of Manchester, UK, won the Nobel Prize in Physics for their

research achievements in graphene.

QS Graphene entered the field of graphene research and development in

2005, and has built a graphene raw material factory, specializing in the

production of graphite oxide, modified graphene and other varieties. In

August 2021, the China Chemical Fiber Association and Japan's Toray

Testing Institute performed an audit of our process, taking random

samples for analysis. The purity of our graphene was 99% which is

the highest quality in China and the rest of the world. The

single-layer rate reached 99%. In China, the single-layer rate of

graphene reaches 99%, with only two companies including QS

graphene.

In 2022, the Global trade association, The Graphene Council

audited our process, obtaining samples for analysis and

inspecting the plant itself. This resulted in QS Graphene

receiving their “Verified Graphene Producer” status, and

the only member that produces fiber products containing

graphene.

QS Graphene specializes in the research and

development of graphene composite fibers, including

polyamide, polyester, polypropylene, viscose,

HDPE, and other functional yarn products. These

fibers have unique functional properties including

cut resistant, thermal regulation, antibacterial,

anti-odor, UV resistance, far-infrared absorption,

and other functions.

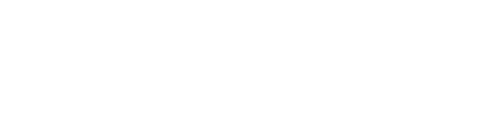

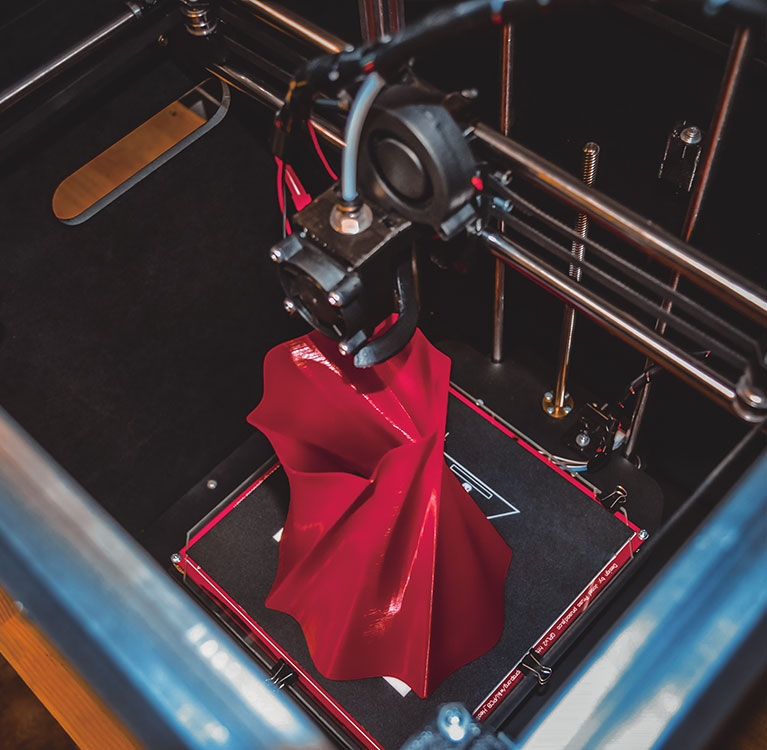

QS Graphene3D Printing Filament Products

3D printing generates objects of various shapes by adding layers of material,

simplifying product manufacturing process, and shortening the product

research development period. It is a typical green intelligent manufacturing

technology with high efficiency and low cost. It is called the carrier of the third

Industrial Revolution, and the key technological means to reshape the future of

manufacturing along with robotics, artificial intelligence and nanotechnology.

The application of this new technology is very broad with applications in in

automotive, aerospace, consumer electronics, medical and health, industrial

design, engineering construction and other fields. Important progress has

recently been made in many fields to commercialize this exciting technology.

The 3D printing polymers themselves are the critical element for 3D printing. At

present, there are a limited number of polymers used, mainly PLA, PETG, and

nylon. One method of strengthening and toughening the filament is achieved

by adding glass fiber, but the desired performance is often not achieved.

Carbon fiber can also be used to improve the strength and toughness, but only

black or other dark colors can be achieved.

Nantong Qiangsheng Graphene Technology Co.,Ltd has developed a line of

printing filaments using white graphene to produce a new ultra-high strength

toughened 3D printing material. Compared with ordinary reinforced materials,

an increase of as much as 35% can be achieved. In addition, the 3D parts can

be produced in white and other light-colored products, broadening the

application field of 3D printing.